Description

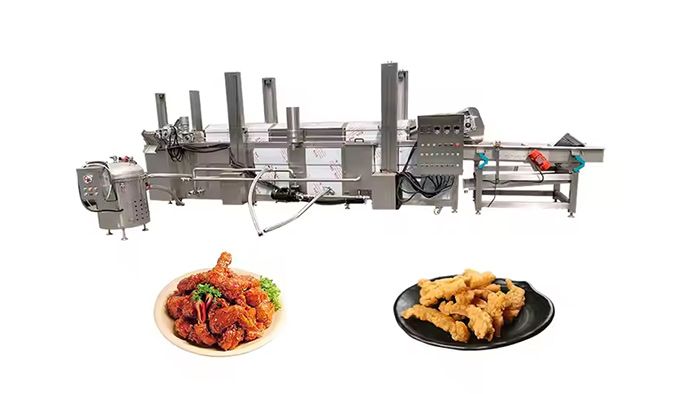

This continuous deep fryer machine can realize continuous working, with high working speed.automatic feeding and discharging. And this machine is multifunctional, suitable for frying all kinds of nuts, peanut, beans, chicken.chin chin etc.. This machine can be used in many production line, such as chicken nuggets,chin chin processing line.

The Design Process of the Snack Frying Line

The frying equipment adopts the method of heating from the middle of the oil layer to control the temperature of the upper and lower oil layers to effectively alleviate the oxidation degree of the fried oil. During the frying process, the principle of different proportions of oil and water is used to automatically filter residual inspection and automatically control temperature. Thereby extending the service life of the oil. The mesh belt is used for transmission, and the mesh belt is adjusted according to customer needs. With high efficiency, high output and high quality of fried products, it is an ideal equipment for medium and large fried food processing enterprises.

In response to customer needs in different scenarios, Weixin has developed a complete set of snack food frying processing technology. The process includes a complete set of production equipment from raw materials to frying. Modular equipment can be freely matched and combined according to customer needs. The production capacity ranges from 100kg/h to 2000kg/h.

In response to customer needs in different scenarios, GELGOOG has developed a complete set of snack food frying processing technology. The process includes a complete set of production equipment from raw materials to frying. Modular equipment can be freely matched and combined according to customer needs. The production capacity ranges from 100kg/h to 2000kg/h.

Work flow of Automatic Fried Production Line

Frying System-Deoling System-Seasoning system

Technical Parameter

| Application: | Kinds of snacks, fried food, puff food |

| Payment: | T/T, Alibaba Trade Assurance, Western Union, PayPal, Alipay, WechatPay, L/C |

| Lead Time: | 30-45working days after deposit |

| Voltage: | We normally make it 220v/50Hz/single phase or 380v/50Hz/3 phases.But it can be made according to your demand, like 110v/60Hz/single phase or 415v/50Hz/3 phases etc. |

| Packing: | For LCL, we use export standard fumigation wooden case |

| Shipping: | Shipping by express, air, railway and sea. |

| OEM: | Customization of nameplate, material, motor brand, packaging, etc. |

Advantage

Adopt internal furnace heat exchanger.

Conveyor belt speed is adjustable for different frying time according to different products.

Collocation with a humanized operation interface.

Electricity, gas or diesel, and also electromagnetism as power source.

Oil level alarm and automatic oil temperature control (0-300°C).

Double belt design to prevent floating, ensure complete and perfect frying effect.

Oil circulation system to continuously filter oil residue and extend the service life of cooking.

Food Application

Meat

Chicken, Fried Chicken Steak, Chicken Wings, Chicken Skin, Fried Pork Chop, Crispy Fried Spareribs, Fried Fish, Fried Pork Knuckle…and others fried meats.

Vegetarian

Tofu, Tofu Skin, Fried Bread Sticks, Vegetarian Meat, Plant Meat, Wheat Wheel, Noodle Gluten, Fried Tempura…etc fried vegetarian food.

Frozen Food And Semi-Product Frying

Hot Pot Ingredients, Chicken Nuggets, French Fries, Fried Cuttlefish Ball, Spring Rolls, Croquette, Dumplings, Seafood Cake…and others frozen semi-products.

Snacks

Banana Chips, Potato Chips, Taro Chips, Shrimp Crackers, Puffed Snacks Food, Green Beans, Corn Curl, Cheetos, Sachima, Noodle Snacks…etc others fried snack food.

Indian Fried Food

Vada, Chanachur, Namkeen, Samosa, Kurkure, Gulab Jamun…and many other Indian fried foods.