Description

Continuous fryer is an automatic and continuous frying system used in automatic chicken nuggets production line, pellet frying line, french fries production line, automatic potato chips production line, banana chips line etc.

Capacity: 100kg/h to 1500kg/h, and customized according to requirement.

Heating Source: Electricity, Gas/LPG gas, Diesel to choose

Materials: Food grade stainless steel 304

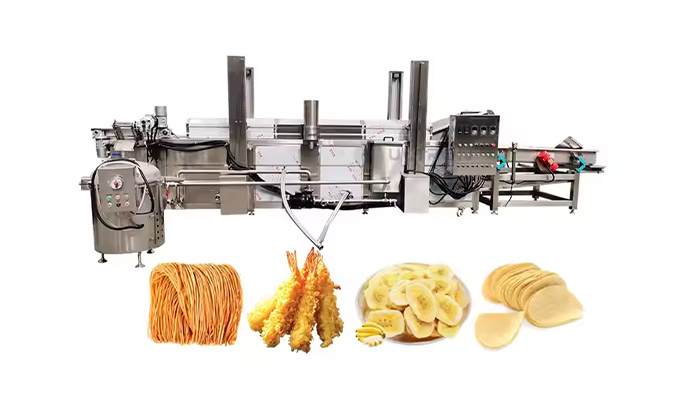

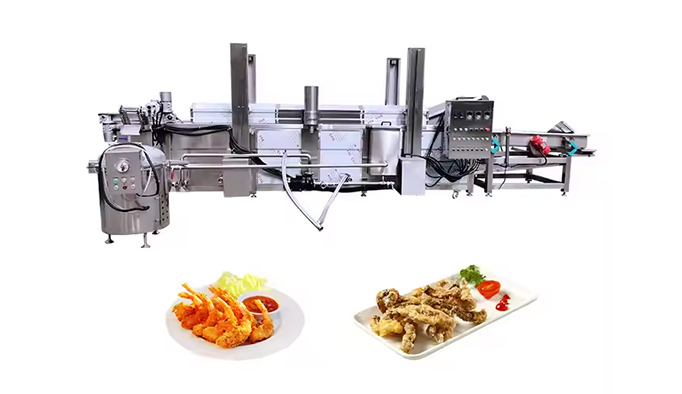

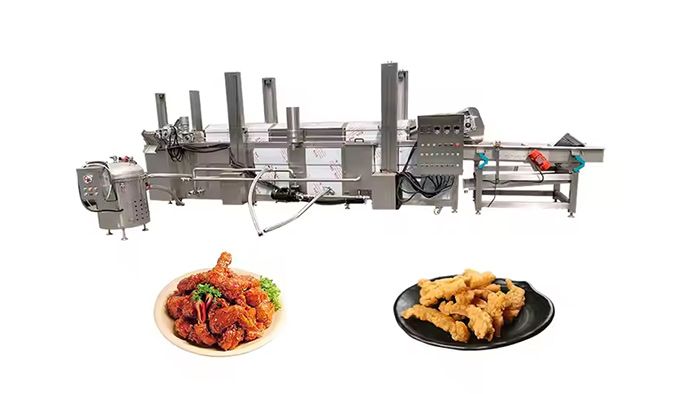

Continuous Fryer Application

Continuous fryer is a fully automatic frying machine to realize continuous frying process, oil temperature control, frying time set, fried food and snacks automatically discharging.Since the frying machine greatly saves labor costs and improve the whole production line efficiency. And because of its many advantages, automatic frying machine is a most preferred choice for food factory production line.

Auto fryers is used for continuous frying chips, nuts, french fries, namkeen, peanuts, cashew nuts, fish skin, pork skin, plantain chips, french fries, potato chips, chicken nuggets, spring rolls, pani puri etc.

Besides, the continuous deep fry equipment plays an important part in automatic food production line, such as automati frozen french fries production line, chicken nuggets processing line, burger frying line, banana chips production line, peant frying line etc.

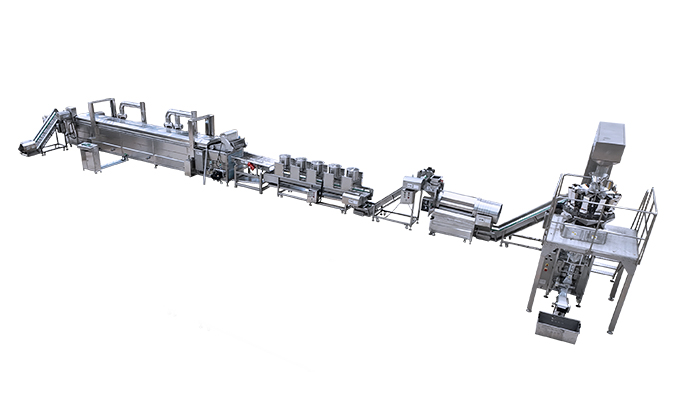

Continuous Frying Machine Introduction

Automatic Fryer Machine Description

Continuous deep fry equipment is a continuous frying system, covering belts transmission to control frying time, belt evelavtion for cleaning, oil temperature control and adjustment.

And the fryer machine is built with double layer mesh belts to sandwich the floating materials into oil complete. And the belts are normally customized based on the frying materials.

Besides, external heating fryer with large capacity also design with residue and waste scrapping system, oil refill system, oil filtering and reserve system etc.

What is more, frying machine is not only used alone in workshops or central kitchen, but also used to continuous working in automatic food production line.

Continuous Industrial Fryer Specification

Heating Method: Electric heating / Gas Heating / Diesel Heating

Machine Materials: Food grade 304 stainless streel materials, best quality made

Temperature Control: Have Automatic oil temperature control system

Oil Heating Temperature: 0℃ to 300℃ (Fahrenheit 32°F to 572.0 °F )

Capacity: 100KG/H to 1500KG/H and customized capacity (according to fryer machine models and raw materials)

Electric Heating Continuous Frying Machine

| Model | Capacity (Raw Material) | Power | Weight | Fryer Size | Oil Temperature |

| DT-CF-3500E | 500kg/h | 80kw | 1000kg | 3500*1200*2400mm | 0-300 ℃(Fahrenheit 32°F to 572.0 °F ) |

| DT-CF4000E | 600kg/h | 100kw | 1200kg | 4000*1200*2400mm | 0-300 ℃(Fahrenheit 32°F to 572.0 °F ) |

| DT-CF-5000E | 800kg/h | 120kw | 1500kg | 5000*1200*2400mm | 0-300 ℃(Fahrenheit 32°F to 572.0 °F ) |

| DT-CF-6000E | 1000kg/h | 180kw | 1800kg | 6000*1200*2400mm | 0-300 ℃(Fahrenheit 32°F to 572.0 °F ) |

| DT-CF-8000E | 1500kg/h | 200kw | 2000kg | 8000*1200*2600mm | 0-300 ℃(Fahrenheit 32°F to 572.0 °F ) |

| Remark: Final capacity for each model is varied according to fried material and its required frying time. | |||||

Advantage

Adopt internal furnace heat exchanger.

Setting multiple safety devices and alarms.

Collocation with a humanized operation interface.

CIP self-cleaning system.

Whole machine is made of stainless steel. Hygienic and durable.

Designed to save energy, space and oil consumption as the aim.

Precision maintain temperature and timing control.