Description

Ginger is a common condiment and a great ingredient. Gingerol in ginger has a certain stimulating effect on the heart and blood vessels. Eating ginger can speed up blood circulation and has a good curative effect. Ginger can be processed into dried ginger chips or slices.

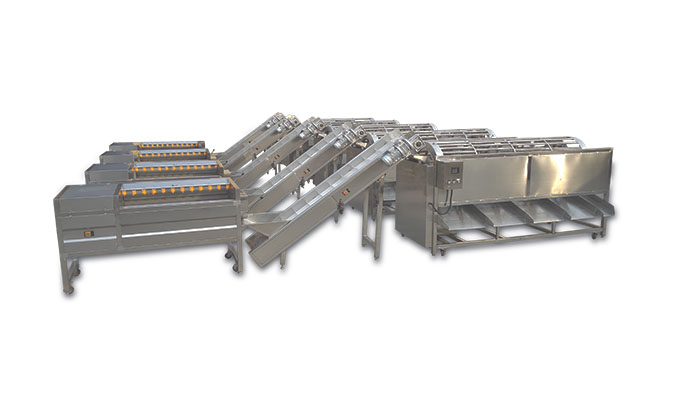

Ginger chips processing line is consisted of ginger washing machine and ginger slice cutting machine. GELGOOG “ginger processing solution” provides all the necessary equipment at one time, as well as a full range of ginger processing planning services. Customized solutions according to your plant size, production plan, market expansion and other needs.

Ginger washing machine: This is multi-purpose washing cleaning machine for various fruit and vegetables, like jujube, carrots, apples, potatoes, potatoes, edible fungus, raisins, green leafy vegetables,etc. This machine using high-quality stainless steel, net chain conveyor, by the vortex inflatable aerator for gas, circulating stainless steel pump for secondary cleaning. Cleaning time can be adjusted according to the actual situation with manual stepless speed regulation motor control. After cleaning the material is transported to the air-dry area, blown out of the fan driven by clean wind, remove the moisture.

☆ Ginger cutting machine: This machine can be used to cut ginger into slices and shreds, only need to change the blade, also suitable for processing potato, carrot, cassava, etc.The ginger chips making equipment is easy to operate, high output, good shape, can be used to cut into slices and shreds, the thickness can be adjusted freely, cut out the film, silk surface is smooth, which is currently the most advanced vegetable cutting equipment.

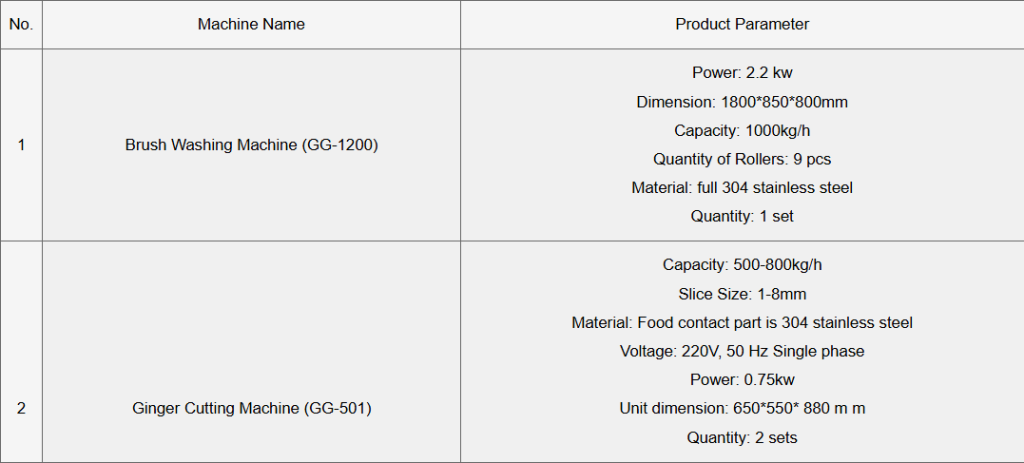

Technical Parameter

Fruits And Vegetable Washing Machine Working Principle

Ginger chips processing line is consisted of ginger washing machine and ginger slice cutting machine. Weshine “ginger processing solution” provides all the necessary equipment at one time, as well as a full range of ginger processing planning services. Customized solutions according to your plant size, production plan, market expansion and other needs.

Product Features

1.The first step is to put the vegetables and fruits that need to be cleaned in the bubble washing machine for cleaning;

2.The second step is to use the conveyor belt to transfer the washed fruits and vegetables to the hair roller washing machine for secondary cleaning to ensure that the vegetables are clean 100%;

3.the third step is to remove some of the water from the fruits and vegetables through the vibrating screen;

4.the fourth step is to remove all the water from the fruits and vegetables from the vibrating screen into the air dryer;

Applications

We specialize in producing all kinds of fruit and vegetable production lines.This is a complete production line, suitable for various types of vegetables and fruits, such as carrot pieces, red dates, cabbage, onions, citrus, avocado, etc.

Applicable scenarios: supermarkets, restaurants, food processing plants, freezing plants, dried fruit processing products.