Description

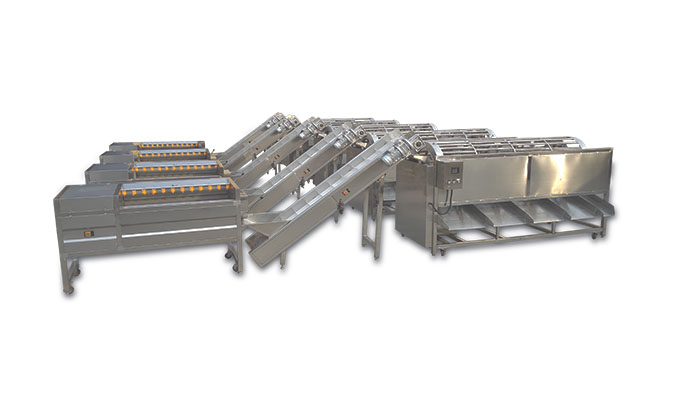

Industrial Fruit and Vegetable Washing Line with Inline Dewatering Machine is a set of automated equipment integrating washing and dehydration, designed for fruit and vegetable processing enterprises, aiming to efficiently and thoroughly wash all kinds of fruits and vegetables. It consists of a lifting conveyor belt, a bubble cleaning section, a spray rinsing area and an inline dehydration module. The whole is made of food-grade stainless steel and is suitable for central kitchens, agricultural product processing plants, hotels and large canteens. This equipment can significantly improve cleaning efficiency, reduce labor costs, and ensure that products meet higher hygiene standards. It is an important part of modern food processing production lines.

Technical Parameter

| Total output of carrot washing line 500-1000 kg / h | Power | Size |

| Item | 3.75kw/380v/50Hz | 4000*1200*1300mm |

| Bubble Washing machine | 3.75kw/380v/50Hz | 2000*1000*1900mm |

| Bubble Washing machine | 2.0kw/380v/50Hz | 2000*1000*1300mm |

| Hair roller cleaning machine | 1.5kw/380v/50Hz | 1500*1000*1300mm |

| vibrating machine | 15kw/380v/50Hz | 4000*1200*1400mm |

| air drying machine | ||

| Note: These parameters are conventional and can be customized according to customer needs |

Fruits And Vegetable Washing Machine Working Principle

Lifting and feeding: Fruits and vegetables are introduced into the washing section by the conveyor through a stainless steel mesh belt to ensure continuous flow of materials on the production line.

Bubble rolling + brushing spray: Use a bubble generator to create underwater tumbling, plus high-pressure water spraying and brushing to remove dirt, agricultural residues and sediment.

Rinse and filter cycle: Two-stage spray system and cycle filtration are set up to achieve secondary cleaning, while saving water and protecting the environment.

Dehydration: After washing, fruits and vegetables immediately enter the online dehydration module (such as belt air knife or centrifugal dehydration) to quickly remove surface moisture and prepare for subsequent cutting or packaging.

Product Features

1.The first step is to put the vegetables and fruits that need to be cleaned in the bubble washing machine for cleaning;

2.The second step is to use the conveyor belt to transfer the washed fruits and vegetables to the hair roller washing machine for secondary cleaning to ensure that the vegetables are clean 100%;

3.the third step is to remove some of the water from the fruits and vegetables through the vibrating screen;

4.the fourth step is to remove all the water from the fruits and vegetables from the vibrating screen into the air dryer;

Applications

We specialize in producing all kinds of fruit and vegetable production lines.This is a complete production line, suitable for various types of vegetables and fruits, such as carrot pieces, red dates, cabbage, onions, citrus, avocado, etc.

Applicable scenarios: supermarkets, restaurants, food processing plants, freezing plants, dried fruit processing products.