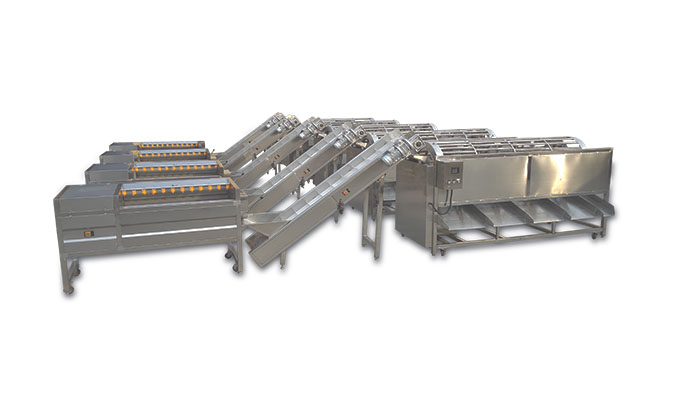

This strawberry processing line is engineered to provide an efficient and hygienic method for handling delicate berries in large quantities. The standard configuration features three main sections: a bubble-type washing machine to gently remove dirt and surface residues, an air-drying conveyor to remove excess moisture, and an automatic slicer for consistent cutting of strawberries into uniform slices.

All machines in the line are constructed with food-grade stainless steel and are easy to clean and maintain. The system is particularly suitable for facilities producing frozen strawberries, dried fruit slices, or pre-processed berries for bakery or snack applications. The layout and capacity of the line can be customized to meet specific production requirements.

Technical Parameter

| Total output of strawberry washing line 1000 kg / h | Power | Size |

| Item | 0.75kw/380v/50Hz | 2000*1000*1900mm |

| hoisting machine | 3.75kw380v/50Hz | 3000*1100*2200mm |

| Drum cleaning machine | 2.0kw/380v/50Hz | 2000*1000*1300mm |

| Hair roller cleaningmachine | 0.75kw/380v/50Hz | 3000*900*900mm |

| sorting machine | 0.75kw/380v/50Hz | 2000*800*1600mm |

| hoisting machine | 1.5kw/380v/50Hz | 1500*1000*1300mm |

| vibrating machine | 15kw/380v/50Hz | 4000*1200*1400mm |

Carrot Washing Line Working Principle

Product Advantages

✔ Complete Washing to Slicing Workflow: Integrates washing, air drying, and slicing for a streamlined process.

✔ Gentle Cleaning System: The bubble washer ensures effective cleaning without damaging soft strawberry surfaces.

✔ Uniform Slicing Output: The slicer offers consistent cuts with adjustable thickness for different product needs.

✔ Sanitary Design: Made entirely of SUS304 stainless steel for durability and food safety compliance.

✔ Customizable Configuration: Layout and capacity can be tailored according to processing scale and site conditions.

✔ Easy Operation and Maintenance: Intuitive control systems and accessible design for daily use and cleaning.

Carrot Washing Processing Line Features

Multi-stage assembly line design

Integrates preliminary mud removal, bubble cleaning, brush peeling, high-pressure spraying and air drying to achieve continuous processing;

304 food-grade stainless steel body

The entire line adopts SUS304 stainless steel, which is corrosion-resistant, easy to clean, and meets European and American export standards;

High-efficiency bubble cleaning system

The bubble tank uses strong rolling to remove surface dirt, and with multi-point spraying device, the cleaning rate is as high as 95%;

Adjustable brush peeling module

Adopting soft and hard brush rollers to effectively remove epidermis and surface impurities without damaging rhizomes;

High-pressure spraying and air drying system

Combined with high-pressure water guns and constant temperature air knives, rapid dehydration and drying provide clean, drip-free products for subsequent sorting and packaging;

Intelligent sorting and rejection

Can be configured with vibration or roller sorting devices to reject unqualified rhizomes according to size or weight to ensure the consistency of finished products.