In the dynamic world of fruit production, efficiency and quality control are paramount. For the pear industry, technological advancements in sorting, grading, and packaging machinery are transforming traditional operations, enhancing productivity, and ensuring consistently superior fruit quality. This comprehensive guide explores the cutting-edge machines and integrated systems that are setting new standards in pear processing.

The Evolution of Pear Processing Technology

Traditional manual sorting and packaging methods for pears have long been plagued by inconsistencies, high labor costs, and potential fruit damage. Today’s automated systems address these challenges through sophisticated technology that handles pears with precision and care while dramatically improving processing speeds.

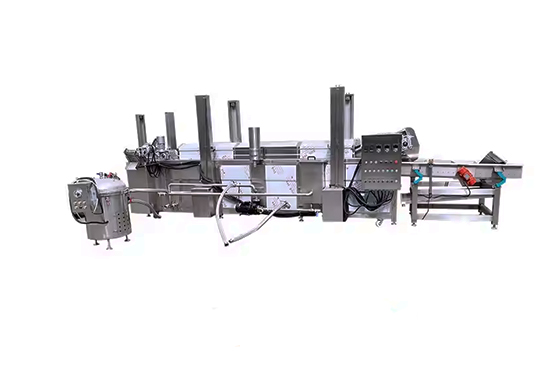

Versatile and robust Uni 9.0 Pear, the electronic pear sorter, incorporates innovative conveying systems.

The highest reliability in the classification of pears is now possible with Uni 9.0 Pear and Pears Sort 3 technology, for the selection and classification of external quality making use of the most advanced technology able to classify each piece of fruit with maximum efficiency and precision.

This innovative technology combines maximum delicacy in the processing of pears and high productivity in small spaces to ensure maximum accuracy in the transport of the fruit, accompanying each single piece in the output descent stage in a super delicate manner in order to protect the integrity of each pear.

The innovative conveyor studied by the Unisorting Research & Development team allows the Pears Sort 3 quality classification system to view every single pear without subjecting it to rotation.

Equipped with a new technology for cleaning and washing the conveyor system, Uni 9.0 Pear uses an automatic system with exceptional characteristics in terms of speed, repeatability, efficiency and reliability over time.

Unisorting technology does a great deal for the pear business. And it does it well.

> Gentleness.

Fruit is handled non-destructively and respecting its qualities.

> Versatility.

Great versatility with multi-analytical technology that’s suitable for all types of pear.

> Traceability.

All the information needed to ensure traceability is recorded, from producers to consumer.

> Flexibility.

Simple calibration and independent management of quality selection parameters.

> High productivity.

A Unisorting plant with Pears Sort 3 can process 3 to 10 fruits per second, depending on the fruit shape.

Reliability. One of Weshine sorting’s key characteristics.

Every Weshine plant is installed with the utmost commitment to agreed standards and to your current and future business.

Unisorting works with you to develop successful ideas.

It aims at turning your targets into concrete results. To help your business grow.

Customization for Specific Pear Varieties

Modern processing equipment can be tailored to accommodate the unique characteristics of different pear varieties:

- Delicate Varieties (such as Asian pears): Enhanced cushioning and lower impact transfer systems

- Size-Based Sorting: Adjustable parameters for different expected size ranges across varieties

- Firmness Considerations: Customized handling pressure based on fruit susceptibility to bruising