Production introduction

Onion processing production lines are mainly divided into onin peeling line, onion dice production lines, onion powder production line, onion ring production line, and onion crisp production line, etc.

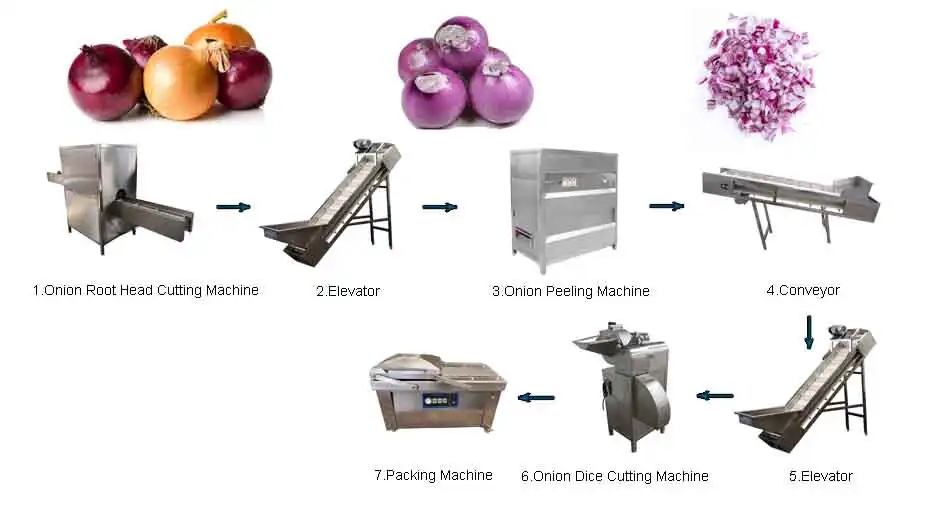

Main Products of Diced onion production line

Onion Root Cutting Machine

All onion processing lines need to cut the head and root of the onion first.

An onion root-cutting machine can quickly remove the head and tail of an onion, which has high output and yield characteristics.

Elevator

After cutting the onion, the onion is lifted to the onion peeling machine at a uniform speed through the elevator.

Onion peeling machine

The onion peeling machine adopts the pneumatic principle.

The peeling process does not go through the blade and hardness friction effect.

With fully automatic digital control, the peeled onion has no damage, a smooth surface, and no pollution.

Conveyor

The conveyor is responsible for transferring the onions under processing between different machines.

Onion Dicing Machine

The onion dicing machine can chop the peeled ones directly into uniform granular dice for easy packaging.

Packing Machine

The packaging machine accompanying the onion powder production line must be customized according to different packaging sizes and materials.